Main features of specialty motors

- Greater radial and axial run-out precision

- Reinforced bearings compared to standard motors

- Self-cooling by means of integrated fan

- Labyrinth seal

- Balancing at rated speed

- Voltage freely selectable

- Converter operating mode

- Variable speed

Options at a glance

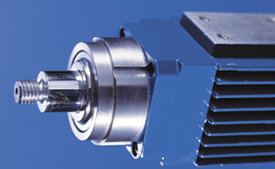

Special shaft, tool mounting

- Cylindrical with / without key with tight rotational tolerance

- Front or exterior threads

- Interior taper (e.g., for holding collets) or exterior taper

- High-precision for radial and axial runout in micronlevel quality

- HSK-C for manual tool changes

- HSK-F63 for automatic tool changes

- Saw blade flange

- Hollow shaft for lubricants or purge air

Bearings

- Spindle or hybrid bearing based on speed and precision requirements

- Single or dual bearing on drive/tool side

Shock loads (e.g., by flying saw)

- Housing and bearing shield are welded steel

Balancing

- Balancing at rated speed also for various operating speeds

- Vibration level R or S

Electrical connection

- Choice of terminal box position (looking at shaft end): front, rear, right, left, axial

- Plug instead of terminal box up to rated current IN ≤ 5 A possible

Motor protection, thermal

- Winding: PTC, PT 100, bimetal switch, KTY sensor

- Bearing: PTC, PT 100

Winding

- Tropical insulation

- Thermal Class H with thermal utilization based on class F

Protection against environmental influences

- Labyrinth seal in special models

- Sealing air for bearings

- Overpressure in the interior in the event of increased humidity

- Dust protection in accordance with ATEX Zone 22

- Anti-condensation heating

- Increased spray water protection

Add-on parts

- Brake, electromechanical

- Rpm indicator

- Mounting flange according to customer specifications